Supply Chain Management

Sustainable Supply Chain Management

Taiwan plays a key role in the global golf equipment supply chain, producing over 80% of golf products worldwide, with Fusheng Precision as a major contributor.

Our production sites span Taiwan, China, and Vietnam, handling international OEM/ODM orders and collaborating closely with upstream steel, metal, and carbon fiber suppliers, as well as top global sports brands—forming a complete and integrated supply chain.

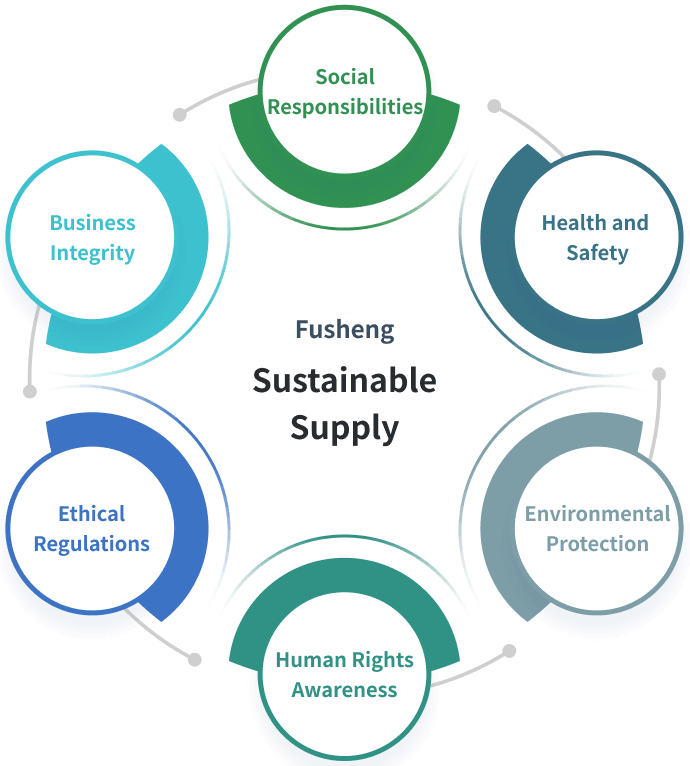

Sustainable Supply Chain Policy

Fusheng Precision views the supply chain not only as an extension of manufacturing, but also as a reflection of corporate responsibility. Our Sustainable Supply Chain Policy requires all partners to commit to:

Respect human rights and ensure health & safety

Protect the environment and avoid conflict minerals

Uphold integrity and follow ethical standards

Through these principles, we work with suppliers to build an innovative, transparent, and mutually beneficial supply chain, becoming a trusted partner for our clients.

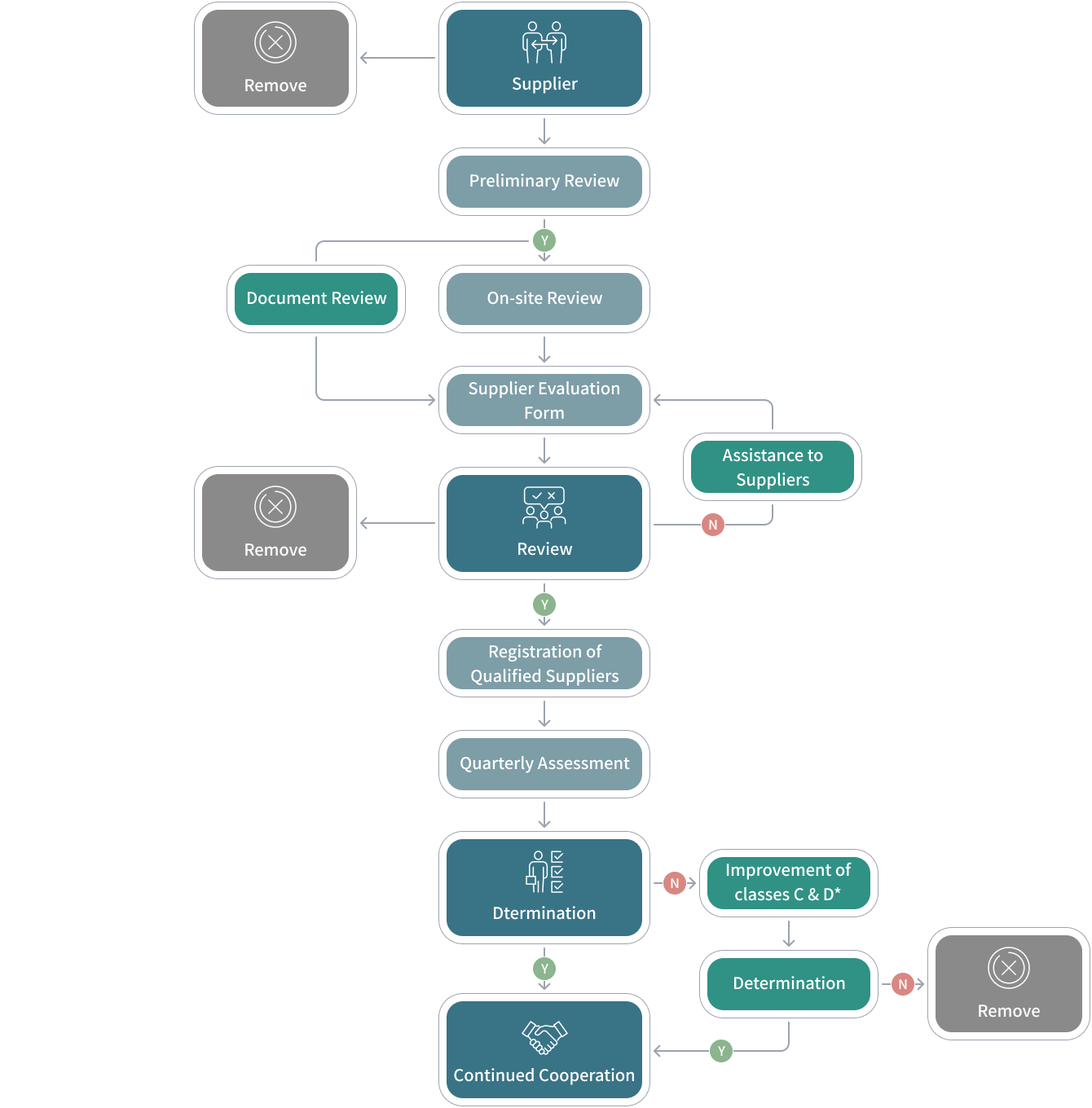

Sustainable Supply Chain Management Process

To ensure a stable and sustainable supply chain, we follow four key steps from supplier selection to continuous improvement:

Stage 1

Selection

Candidates submit a Supplier & Customer Change Form and undergo on-site evaluation by the technical and quality teams. Assessment covers quality, delivery, pricing, service (including EHS), and R&D capability.

Stage 2

Evaluation

The Quality, Technical, Procurement, and EHS teams jointly evaluate suppliers. Approved suppliers are added to the Qualified Supplier List after project manager authorization.

Stage 3

Registration

Approved suppliers sign the Purchase Agreement and Integrity Commitment, then are officially recorded in the Qualified Supplier Database, including approval scope and status.

Stage 4

Assessment

Quarterly reviews monitor quality, delivery, service, R&D, and EHS performance. Suppliers not assessed quarterly undergo annual evaluation to ensure continuous improvement across the supply chain.