Sustainable Carbon Fiber Sports Solutions

A New Strategic Positioning: Vertical Integration of Advanced Materials & Molding Technology

Leveraging Fusheng’s mastery in carbon fiber composites and automated mass production, we integrate innovative design with precision engineering. Our mission is to enhance athletic performance and quality of life, establishing ourselves as the most innovative and sustainable leader in composite material solutions for the global sports and leisure industry.

Driving a Greener Future with Fusheng; Delivering Innovation with Purpose.

Core Integration Strengths

In-house Resin System R&D

Developing proprietary resin systems to create high-performance composite solutions that lead the industry.

Diverse Structural Design Expertise

From Unidirectional (UD) to Twill weaves, we provide comprehensive construction capabilities to bring clients’ product designs to life.

Integrated Multi-process Manufacturing

Our versatile manufacturing techniques meet any product specification, including:

Solvent-free Hot Melt Prepreg

Roll Wrapping & Compression Molding

Bladder Molding & Autoclave Processing

Thermoplastic (TP) Molding

Foam-core Heat Pressing

Cross-industry Integration

We offer more than just materials; we provide scalable mass-production solutions across various industrial sectors.

Innovative R&D and Design Excellence

Core R&D Dynamics(Carbon Fiber Composites)

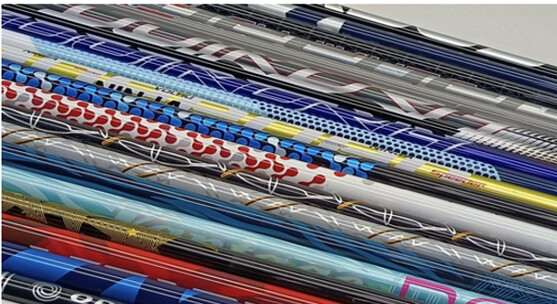

Rooted in deep precision engineering, Fusheng combines advanced composite molding, structural design thinking, and material science to craft high-end sports equipment that balances peak performance, structural integrity, and premium aesthetics. During R&D, we go beyond layup design and mechanical analysis; we actively partner with brands on product strategy—from concept and functionality to visual identity. Each carbon fiber club is a testament to the perfect harmony of engineering, craftsmanship, and design.

The Spirit of Excellence

Guided by the philosophy of “Seeking Truth and Excellence,” we constantly optimize design processes to enhance durability and feel, meeting international competitive standards.

Global Brand Partnerships

Long-term collaboration with world-leading brands to master global market trends and cutting-edge innovations, acting as the innovative force behind global leaders.

R&D Strength & Technical Integration

Continuous investment in R&D and material science to develop high-performance, high-value-added clubs and accessories, providing customized turnkey solutions.

Design Advantages & Technical Integration

We seamlessly bridge the gap between design innovation and composite engineering. By integrating market insights, material selection, and structural verification, we have built a core capability that spans the entire product development lifecycle. Our expertise in layup design and mechanical simulation ensures every product meets international standards and the specific performance needs of diverse player profiles.

Design Advantages

- Market-driven product strategy

- Balance of structural integrity & aesthetics

- Cross-disciplinary collaboration

- User-centric detail engineering

Technology Integration

- Advanced layup & mechanical analysis

- Multi-process technology integration

- Comprehensive engineering verification

- Systematized product development platform

Manufacturing Strength and Global Footprint

Fusheng Precision centers its manufacturing operations in Vietnam, building a highly efficient and automated global production network.

The Vietnam facilities account for approximately 75% of global golf club exports, serving as a key partner for global brands by ensuring stable supply and rapid response.

In 2024, the company achieved revenue of NT$28.3 billion, with continued growth expected in 2025, demonstrating strong momentum in its global market expansion.

Total global shipments demand share

Taiwan, China, Vietnam

Multiple global locations with flexible production capacity

Vietnam’s share of total global shipments

Key Strategies

Continuous Innovation

Aligning with global trends to deploy next-generation carbon composite materials and molding applications.

Smart Manufacturing

Implementing automation and AI-driven production to maintain cost and quality competitiveness.

Sustainable Transformation

Strengthening low-carbon, bio-based, and recycled material technologies to meet global ESG and supply chain standards.

Market Expansion

Applying composite solutions across industries to diversify our global client base.

Quality Control & Assurance System

Fusheng adheres to rigorous quality management and full-cycle testing to ensure every material and finished product surpasses international composite certifications.

Material

Inspection

Fiber consistency,

sizing/linear density checks,

resin/fiber content analysis.

SPC

Monitoring coating temperatures,

weight precision,

impregnation gaps.

Finished Product Validation

Comprehensive mechanical testing, physical property checks, NDT

Full Traceability

Complete records of material batches,

process parameters,

test history.

Looking for a Trusted Manufacturing Partner?

Let our technology and experience support you through the critical stages from 0 to 1.